上洋微信公众号

-

E-mail

E-mail

lyc@sybzcn.com

Flexible package is defined as any package made by laminating two or more s of films, and it can be plastic films, lized materials like aluminum foil and flexible materials like paper. Different printing substrates offer different visual appearances and a combination of different materials also results in different product features, such as printability, a high level of barrier protection, resistance to low temperature and medium. Flexible packages are also designed to protect products during transportation, add convenience in handling, increase product’s purchase appeal and communicate information to potential purchasers. Flexible packages are applicable to a wide range of industries like dairy products, food, drugs and electronic products.

More>

1、To make products marketable and usable, and add value to products; 2、To offer products protection, serve as a barrier to sunshine, wind, rain, dust and other natural hazards and protect products from volatilization, leakage, deterioration, becoming loose or containment to ensure safety of consumers when using products. 3、To add convenience in storage, transportation and selling to ensure successful delivery, and make it easier for purchasers to carry, open and use the products. 4、To encourage potential buyers to purchase a product, make products more attractive to potential buyers and increase sales of products.

More>

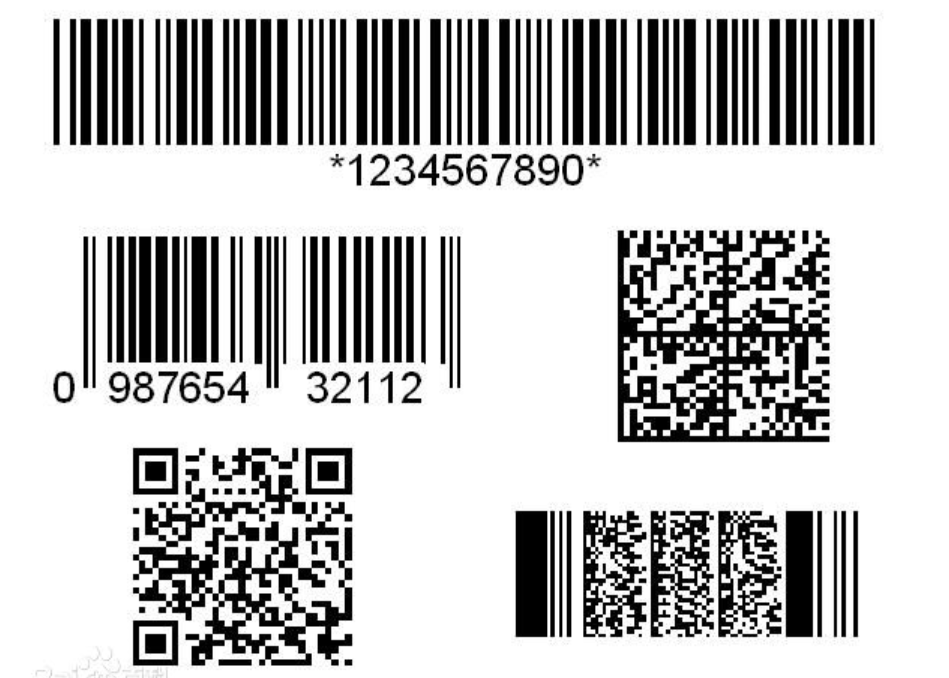

1、Operators at qualified printing companies have received professional training on bar code printing, acquired professional skills and developed a strong awareness of bar code quality, so they are able to identify problems in bar code design in a timely manner and play a key role in bar code quality control with system members; 2、With more advanced printing machines and technologies, they can produce bar codes up to standards; 3、With a complete and effective system for bar code printing contracting, design, printing plate production and printing management, they can ensure high quality bar code printing; 4、With a stringent bar code inspection system, they can minimize the possibility of delivery of nonconforming bar codes and ensure high quality bar code printing to make possible the best use of bar codes and protect companies from loss due to nonconforming bar codes.

More>

1、Aluminum-plastic flexible packages and aluminum-paper flexible packages: for these nontransparent packages, jus use colors as appropriate. 2、Single PE packages: for these transparent packages, the color of the products the package is used for can be use as a complementary color, background color or decorative color (color of the transparent space), depending on the style of your design. 3、The color of products in liquid form, like milk, soybean milk and juice, can be used as the background color of their flexible packages. 4、The color of products in granule form, like coffee and monosodium glutamate, can be used as the background color of their flexible packages. 5、Some products in relatively larger pieces, like dried fruit and preserved fruit, are not recommended to be used as the background color of their flexible packages. For these packages, designers are recommended to leave a transparent space on the package, or use nontransparent color on the entire front side while just printing texts on the back side to make the products visible. 6、There must be a sharp contrast between the bar code and the background color, and the product the package is used for cannot be used as the background of its package for fear that the barcode fails to be read by the barcode reader. 7、There must be a sharp contrast between the texts and the background color to ensure that the texts are readable.

More>

1、The storage of many food products requires protection from exposure to light, and this type of packages can do so and extend shelter life of products. 2、This type of package can help to keep out moist and oxygen and thus keeping the good taste of products.

More>

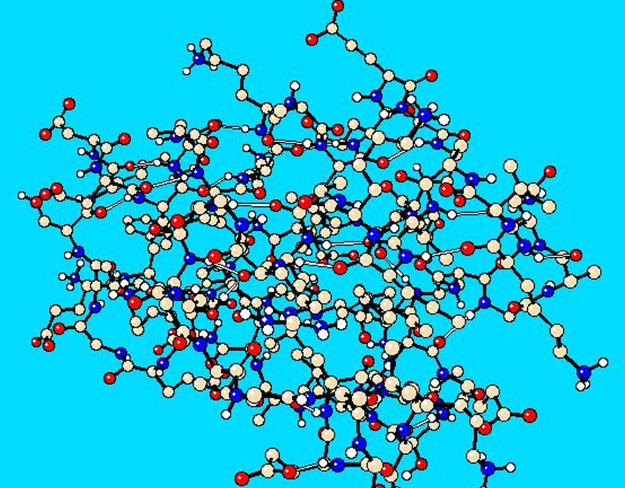

1.Non-polarity of the molecular structure Among main printing substrates for plastic film packaging, PE is a non-polar macromolecular organic compound with low critical surface tension, obvious inertia and poor compatibility with printing ink. Each unit of PP contains a methyl group, a group with low polarity. PP is also a non-polar macromolecular organic compound, but it features higher critical surface tension than PE, so it is more compatible with printing than PE. 2.Low surface energy Plastic films like PE, PP, PET and PVC feature low surface energy. For macromolecular polymers, the lower the surface energy is, the lower the surface tension is and the harder the surface will be wetting. These are problems polyolefin plastic has. To ensure that printing ink can fully wet the printing substrates, the surface tension of the printing substrates is required to be equal to or higher than that of the printing ink. Surface finishing is the only way to improve surface energy of polyolefin plastic.

More>

Back to top

Inquiry via message